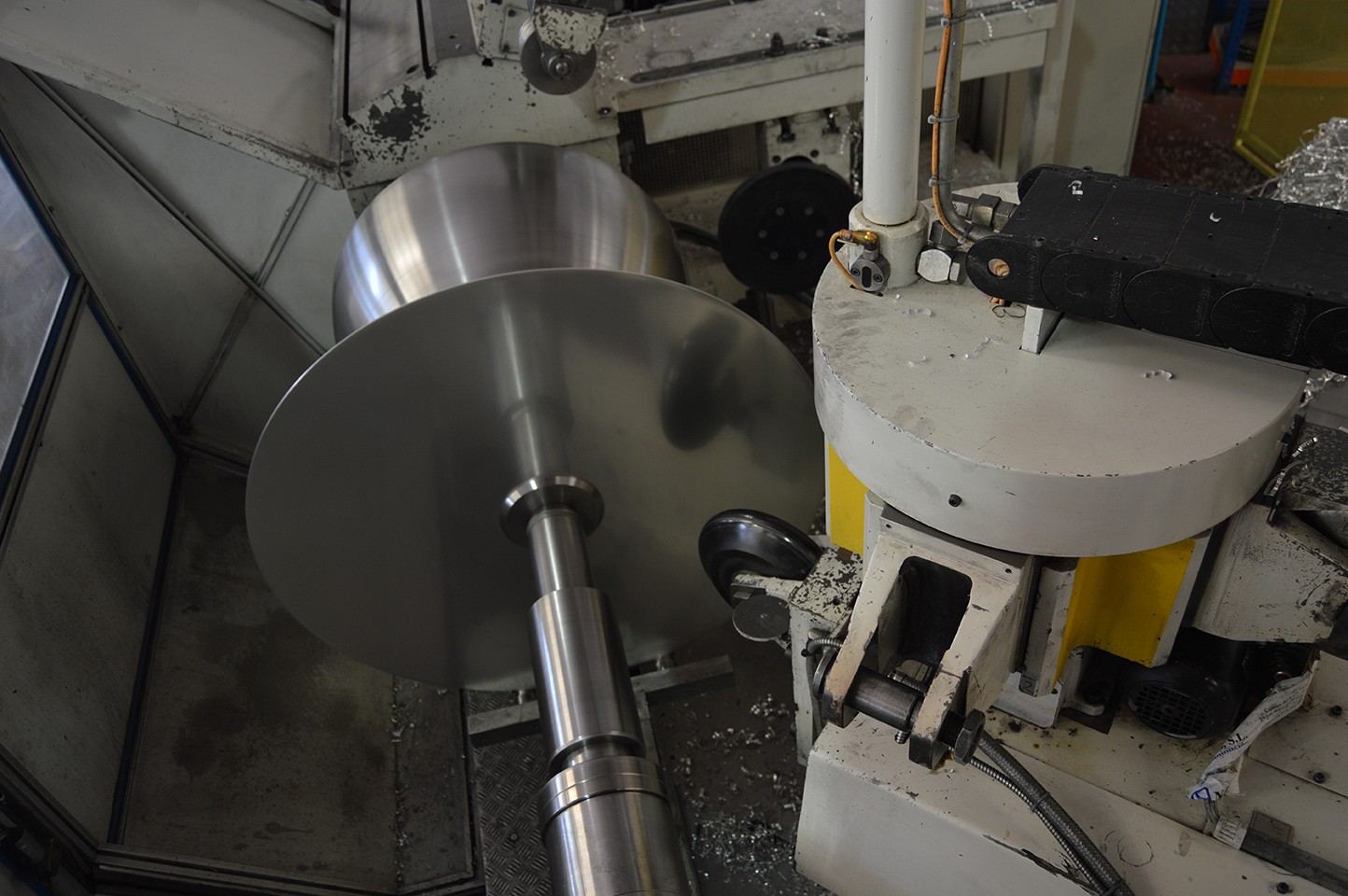

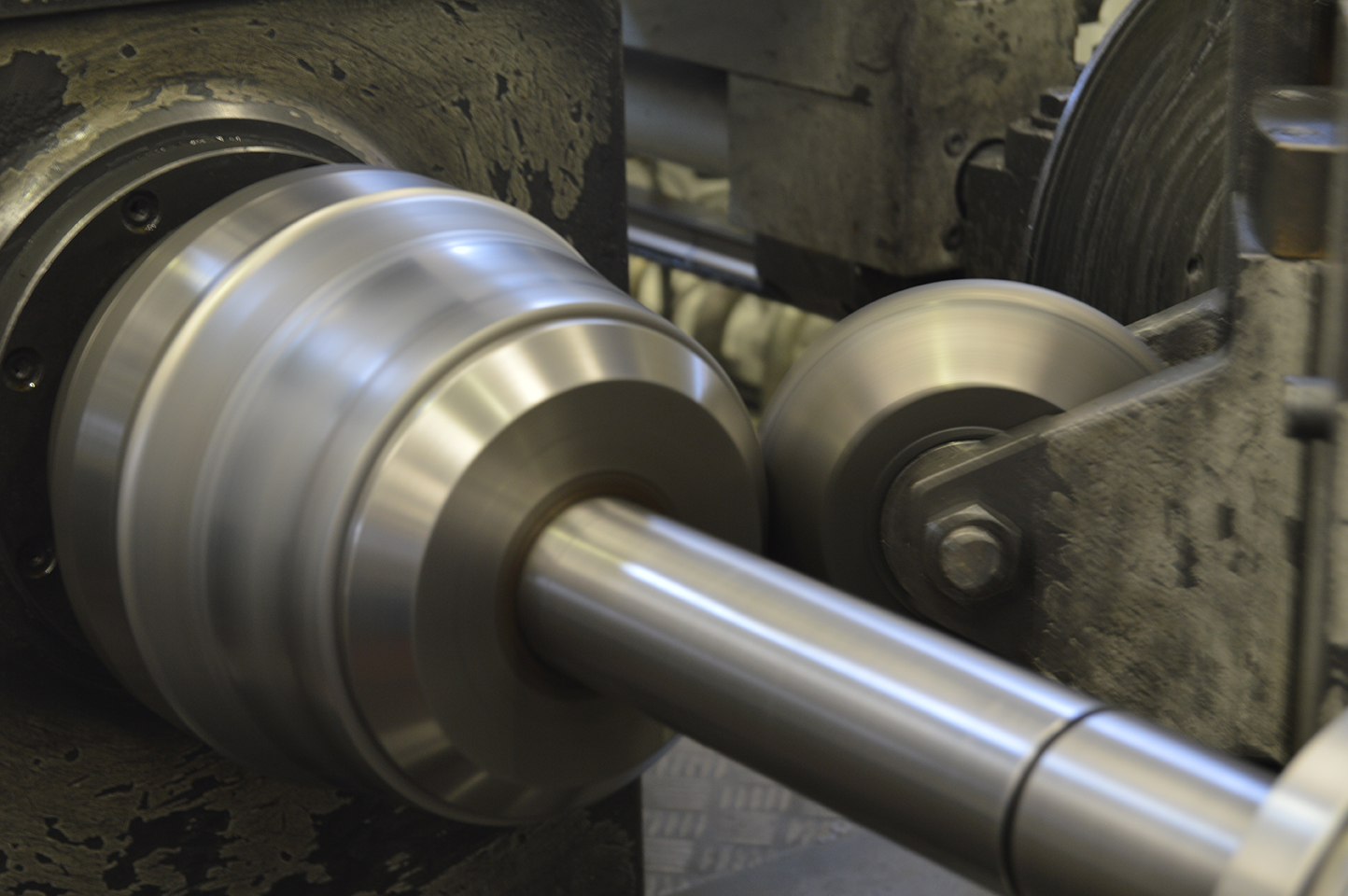

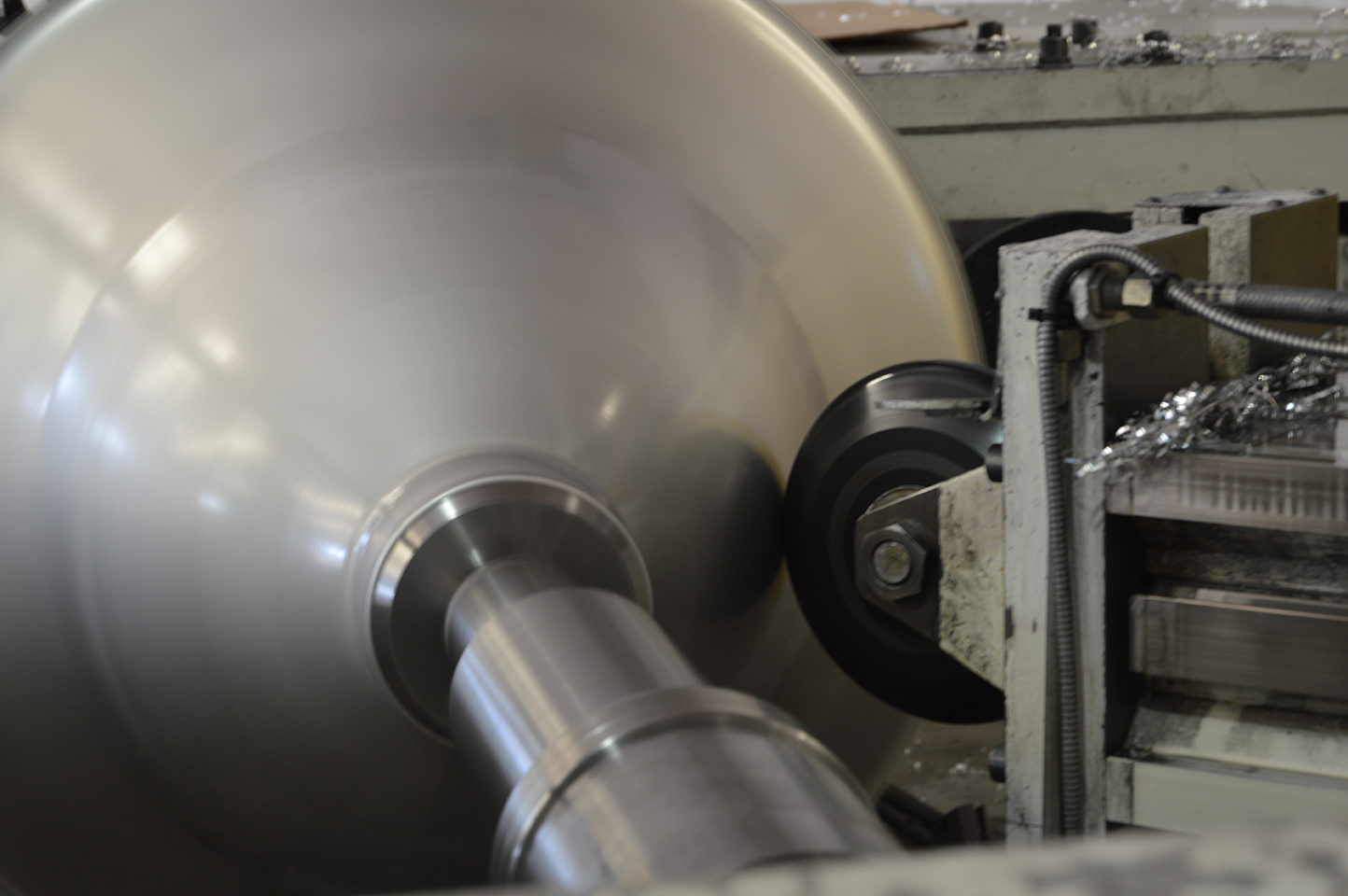

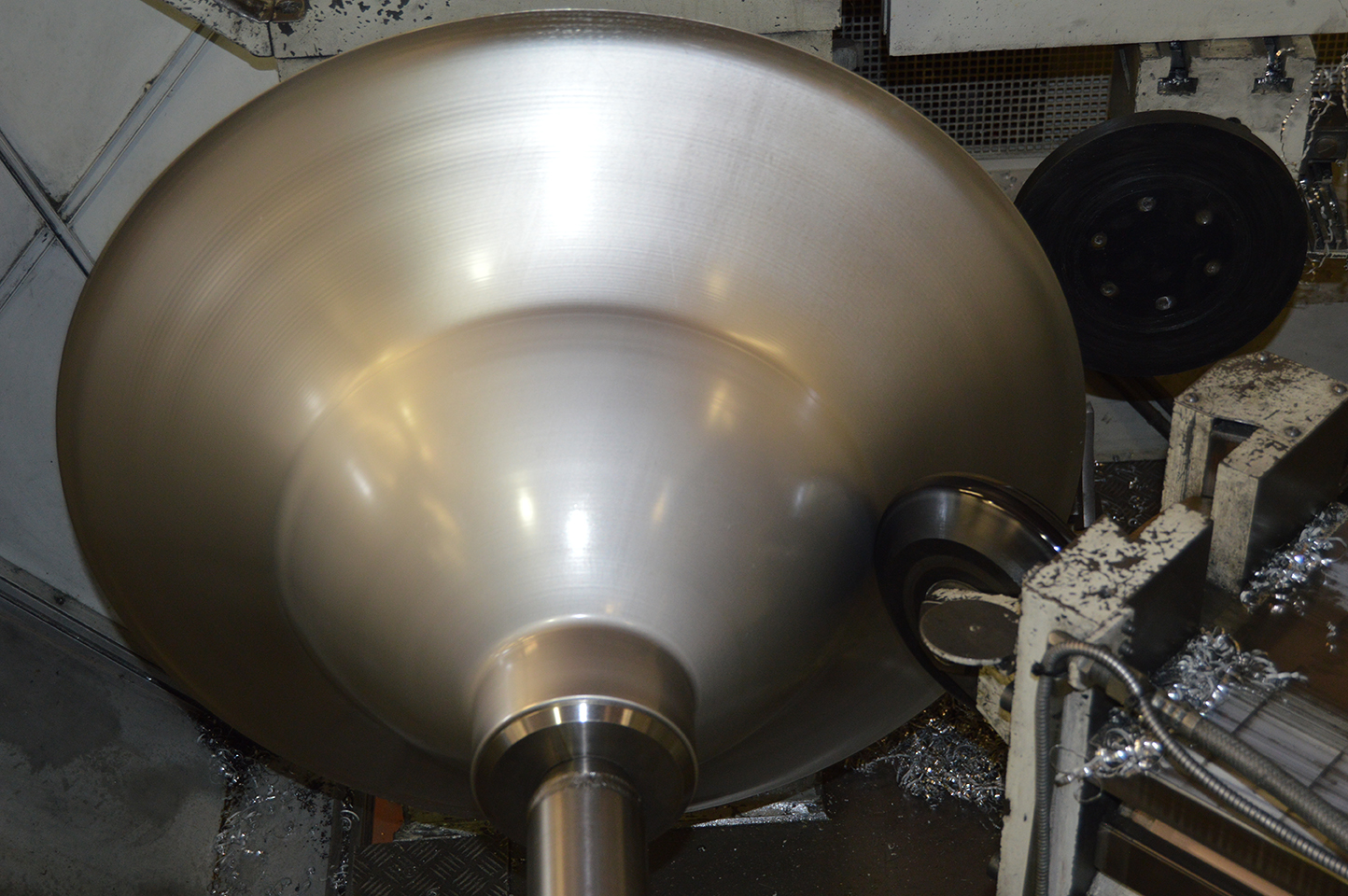

Spinning, also called metallic notching consists of giving shapes to metal pieces through a rotation system made up of a lathe, and a deforming roller that exerts pressure on the piece while it rotates.

To obtain the best result, at TEI NOGAL we have state-of-the-art machinery for repulsed.

Thanks to this and to CNC systems, we can obtain parts with complicated shapes that would be impossible to achieve with other types of repulsive machinery or would greatly increase production costs.

Advantages of the repulsed

The advantages of shaping metal parts using repulsive systems are many, but the main ones we could say are:

- A high deformability.

- A great increase in hardness and resistance.

- Some more uniform finishes.

In addition, with the spinning systems, complex shapes can be created, significantly reducing production costs.

Another advantage of spinning is the variety of metals that can be used, aluminum, bronze, steel, iron as well as high-resistance alloys…